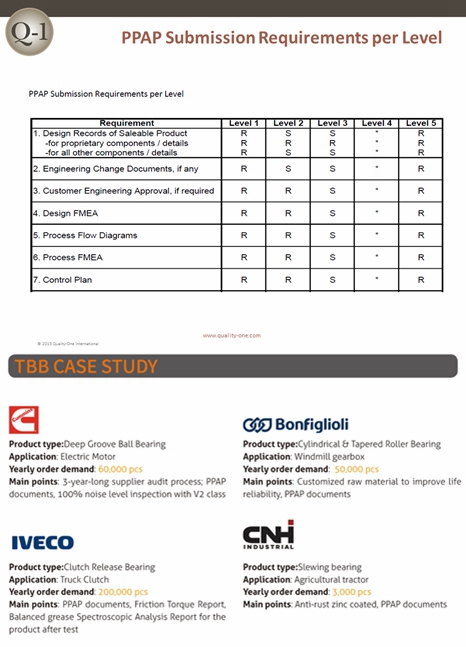

●What is PPAP? PPAP is the abbreviation of Production Part Approval Process, a valuable tool for establishing confidence in component suppliers and their production processes. Initially, PPAP was util…

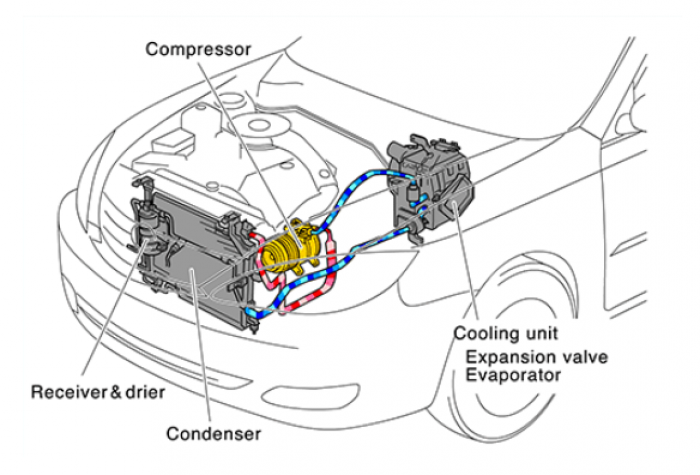

Much like a heart in a human body, the compressor circulates the system’s lifeblood, in this case the refrigerant, that is vital to the proper operation of the air conditioning (A/C) system.The world-…

Rolling element bearings are available in a variety of types, configurations, and sizes. When selecting the correct bearing for your application, it is important to take these factors below into consi…