Vibrating screen bearing is a kind of special bearing designed for vibrating screen equipment, which can maintain stable operation under high-speed vibration, cyclic impact and heavy load conditions, …

Automotive air conditioning compressor bearings are experiencing the transition from ‘mechanical components’ to ‘intelligent systems’. New energy models of high-pressure, high-temperature, high-freque…

Wheel bearing is one of the key parts of the car, its main role is to carry the weight and provide accurate guidance for the rotation of the wheel hub, which requires it not only to withstand the axia…

Guardian of Motor Performance-Insulated Bearing Motors, as the heart of industry, the stability and durability of their performance is more than ever the key to measuring the performance of the entire…

Introduction Have you ever heard about ball-bearing units? Or do you want to know about all the basic knowledge associated with ball-bearing units? No matter what the question is, this article will he…

Introduction If you belong to the agricultural sector, you must be aware of the importance to use right bearings in agricultural sectors so that the agricultural equipment must be able to withsta…

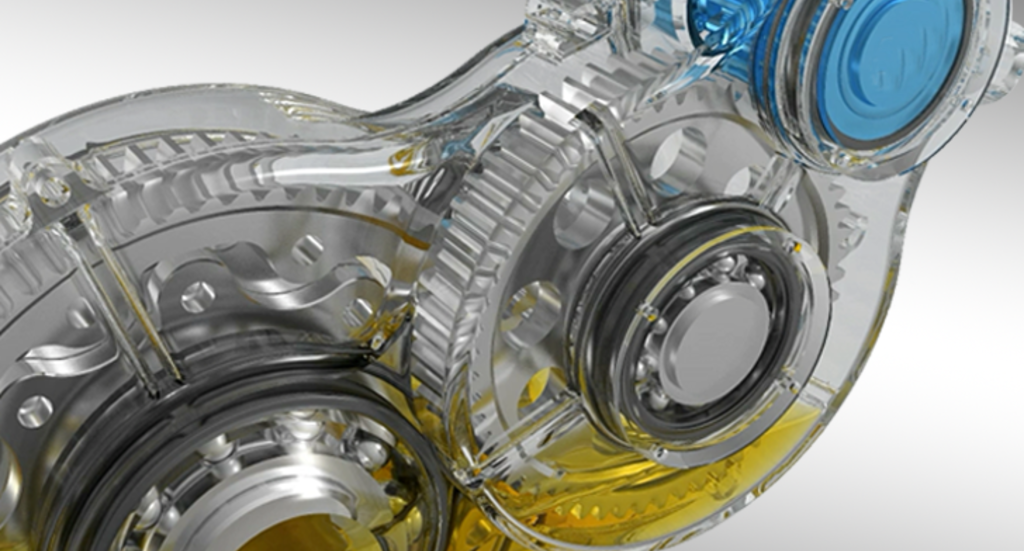

what full-complement cylindrical roller bearings are, common types of full-complement CRBs, those ones popularly used in the gearbox sector, and the reasons and the key quality control points.

“How do we know which lubricant is the most appropriate for the gearbox application?”

Has this question even come to your mind? According to our research, this is the hottest topic our readers pick up for us.