/..: Standardized rolling bearings with uncoded inner diameters A: Single row angular contact ball bearing with 30° contact angle AC: Single row angular contact ball bearing with 25° contact angle ACD…

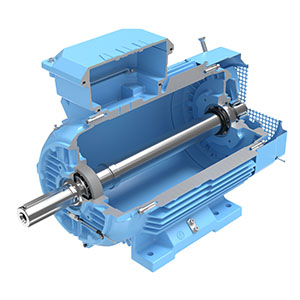

Key Factors of Electric Motor Bearing Design –Outline dimensions–Load size and direction–Speed requirements, constant/variable/high–Material of motor shaft and housing–P…

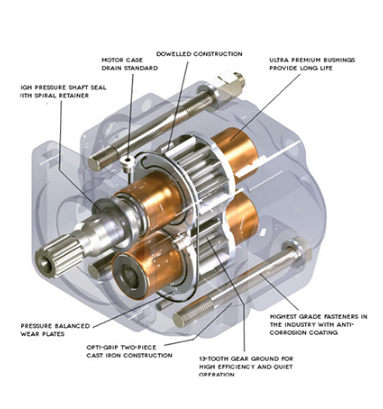

From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. But hydraulic machines are nothing without their hydraulic pumps.The hydraulic pump is…