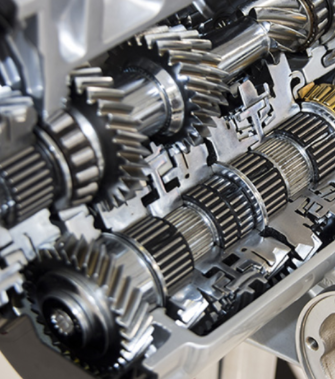

The type of machinery is different, the service conditions of the bearings will be different, and the performance requirements are also different. Generally speaking, there are more than two bearings …

Bearing Selection Guide The types, structures, and sizes of rolling bearings are diverse. In order to make the mechanical device play the expected performance, it is very important to choose the most …

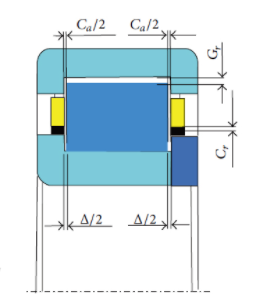

Have you ever noticed the types of cage guidance of your bearings? Basically, there are 3 types: outer-ring-rib guidance, inner-ring-rib guidance, and rolling-element guidance. Unfortunately, big par…