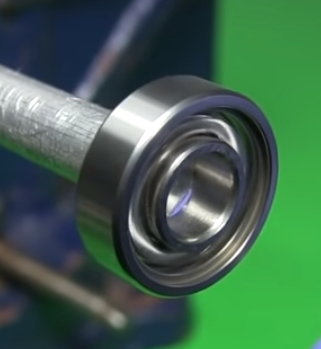

Get out the surgical gloves when working around the most fragile of bearings. Dynaroll miniature ball bearings make a dime look large. (Left)Grooves make room for adhesive to flow without raising runout. (Right)Make sure the shoulder rim clears the opposing ring when locating a bearing against a shoulder in a mating part: Maximum shaft shoulder diameter = Outer ring land diameter – clearance Minimum housing diameter = Inner ring land diameter + clearance A clearance of >0.01 in. allows for normal tolerances. Also, make the shoulder corner radius ra less than the bearing fillet radius, r, so bearings fully seat against shoulders. Most bearing catalogs give these specs. Miniature and instrument-sized ball bearings excel in jobs needing predictable levels of torque, runout, and stiffness. Here, tolerances and finishes measured in millionths of an inch boost precision. However, small size and thin raceways make miniature bearings vulnerable to damage from contamination and high handling forces. Bearing makers typically package the units in Class 100 clean rooms after final inspection because even submicron particles can raise torque and noise levels and shorten bearing life. For users, a clean room or laminar flow workbench is recommended but not required for most assembly jobs,…

Limiting speed values for instrument bearings are almost impossible to determine. However, generalizations may be made. Bearing size: Highest speeds may be obtained with the smallest bearing. However, extremely small miniature bearings usually have a thin, weak retainer and their maximum speed is less than medium-size miniatures. Load: Limiting speed is directly affected by the magnitude of applied load. Heavy loads result in a decreased speed capability. Use of a preloaded pair of bearings also decreases allowable speed. Ring rotation: Inner-ring rotation gives higher speed capability. If the outer ring is rotating, limiting speed must be reduced by about one-third. Retainer: Phenolic (and some other nonmetallic materials) — very high speed; crown (hardened steel) — high speed; ribbon (loosely clinched) — low speed; full race — moderate speed; spacers (PTFE) — very low speed. Lubricant: Stiff, mineral-oil grease — high speed; soft, synthetic-oil grease — moderate to high speed; soft, silicone grease — low to moderate speed; mineral oil — high speed; synthetic oil — moderate speed; silicone oil — low speed. Lubricant method: Oil impregnation and grease pack — excellent; oil impregnation — very good; grease pack — good; minimum oil — fair. Machine Design