Bearing is an important part of mechanical rotation, and its stiffness and working temperature will directly affect the bearing efficiency on the mechanical operation. In order to provide the rotation accuracy of the bearing, increase the rigidity of the bearing device, and reduce the vibration of the shaft when the machine is working, the preloaded rolling bearing is often used, such as the spindle bearing of machine tool.

The bearing stiffness is the force required to produce a unit deformation.

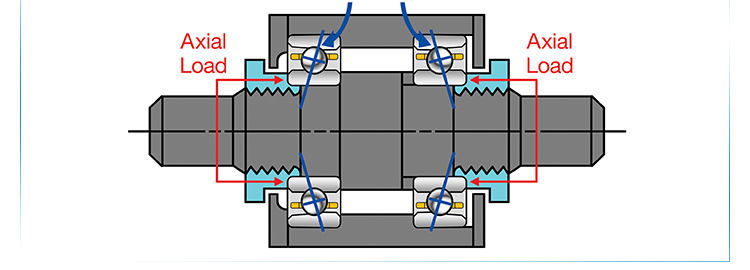

The elastic deformation of rolling bearing is very small, which can not be considered in most machines. However, in some machines, such as machine tool spindle, bearing Stiffness is an important factor, in which case generally cylindrical roller bearings and tapered roller bearings should be selected. Because these two kinds of bearings are in line contact with the raceway when they are under load, they have small elastic deformation and good stiffness. All kinds of bearings can also be preloaded to increase the support stiffness. Such as angular contact ball bearing and tapered roller bearing, in order to prevent shaft vibration and increase support stiffness, a certain axial force is often applied in advance during installation to make them compress each other. Of course, the preload should not be too large, which will cause bearing friction increasing, temperature rising and affecting the service life of the bearing.

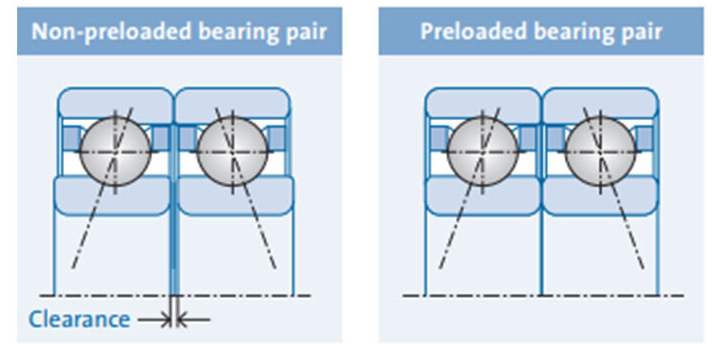

The so-called “Pretightening” is to generate and maintain an axial force in the bearing in some way during installation, so as to eliminate the axial clearance in the bearing and produce deformation at the contact between the rolling element and the inner and outer rings.

Due to the effect of preload, the contact area between the rolling element and the inner and outer rings will produce elastic deformation, and the contact area will increase, and the number of rolling elements participating in the bearing force will increase. It is possible for the rolling elements to participate in the force in the range of more than 180 degrees, and sometimes even all the rolling elements may be stressed in the range of 360 degrees. This is certainly better than a few rolling elements, and it can take more load. From the above discussion, it can be seen that when the preloaded bearing is under the same load, its contact deformation is certainly smaller than that of the non preloaded bearing, so it can improve the support stiffness of the bearing, and at the same time, it can compensate certain wear of the bearing in use.

When the preloaded bearing is under the working load, the radial and axial relative displacement of the inner and outer ring is greatly reduced than that of the non preloaded bearing. For tapered roller bearing with positioning preload, the preload is reduced due to the running in of the rib and the roller end face, so the temperature of the bearing drops correspondingly after running in for a period of time. The larger the preload, the more significant the temperature drop caused by the running in of roller and rib. Under constant pressure preloading, even if running in occurs, the actual level of bearing clearance (preloading) and axial load does not change, so the bearing temperature remains unchanged.

Pretightening Methods of Rolling Bearing:

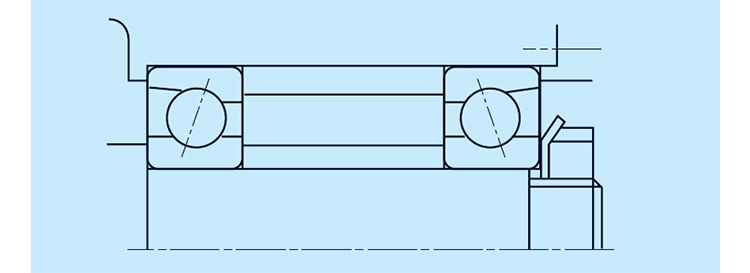

1. Positioning Preloading: the spacing of the combined bearing or the preset inner and outer ring spacer is kept constant, so that the bearing can be properly preloaded.

Due to the influence of the working state and external environment of the bearing, the bearing seat size and bearing parts will also change accordingly, thus affecting the preloading state of the bearing. The preloading method is beneficial to improve the rigidity of the bearing, but the influence of the preloading on the bearing performance should be paid attention to.

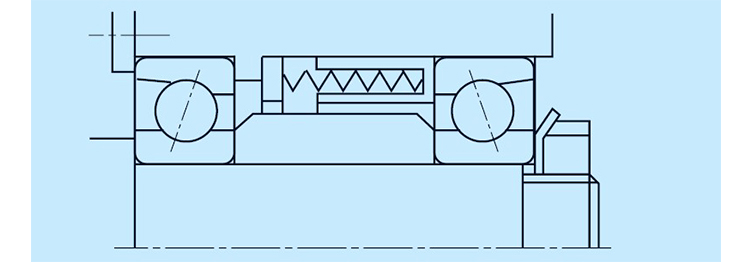

2. Constant Pressure Preloading: is the use of spiral spring, butterfly spring and other elastic components, so that the bearing in the support to get the appropriate preloading. With constant pressure preloading, the movement of the bearing under normal working conditions will not affect the preload, but the stiffness class of the bearing is low, so it is suitable for high-speed rotating occasions, but not suitable for bearing applications requiring high stiffness, bearing direction change or uncertain impact load may occur.

1.Influence of Preload

With the increase of preload, the radial, axial and angular stiffness of the bearing increase slightly, but the effect is very small. Compared with positioning preloading, this effect on constant pressure preloading is more significant. The reason is that the increase of preload makes the contact angle of inner and outer rings increase, and also makes the contact load increase, so that the radial, axial and angular stiffness increase. However, the change of contact load and contact angle caused by preload is smaller than that caused by rotation speed and part displacement, so the influence on bearing stiffness is limited. This is also the reason why the change of the positioning preload is less than that of the constant pressure preload.

2. Influence of Raceway Curvature Radius

With the increase of the curvature radius of the inner and outer raceway, the radial, axial and angular stiffness decreases, but this effect is very small, only the change of the stiffness is slightly obvious under the positioning preload, which is due to the increase of raceway curvature radius and the increase of contact deformation. Therefore, the influence of the curvature radius on the stiffness can be ignored.

3. Influence of the Number of Balls

Under the condition of positioning preloading, the radial, axial and angular stiffness increase slightly with the increase of the number of balls. But the contact load decreases with the increase of the number of balls under the same preload.

Under the condition of constant pressure preloading, the radial stiffness increases s犀利士 lightly with the increase of the number of balls. When the speed increases to a certain value, the axial and angular stiffness decreases, but the change is very small. The reason is that under the condition of constant pressure preloading, although the contact load of the inner ring decreases, the contact angle of the inner ring decreases with the increase of the number of balls. This leads to the increase of radial stiffness, while decrease of axial and angular stiffness.

Therefore, when the number of balls increases, the preload should be increased accordingly. Only when the contact load is the same, can the stiffness of the bearing be increased by increasing the number of balls.

4. Influence of Ball Diameter

Under the condition of positioning preloading, when the ball diameter increases, the radial, axial and angular stiffness increases slightly. The increase of ball diameter makes the centrifugal force of the ball increase, the contact angle of outer ring decreases, and the contact angle of inner ring increases, but at the same time, the contact load of inner and outer rings increases. This leads to the increase of bearing stiffness. The influence of centrifugal force change on contact load is small under positioning preloading, so the influence of ball diameter change on stiffness is very small.

Under the condition of constant pressure preloading, the radial stiffness increases with the increase of the ball diameter, while the axial and angular stiffness decreases, but the influence is small. This is because the increase of the ball diameter increases the centrifugal force of the ball, the contact angle of the inner and outer ring decreases, the outer ring contact load increases, while the contact load of the inner ring is basically the same, so the radial stiffness increases, while the axial and angular stiffness decreases slightly.

Therefore, reducing the ball diameter not only improves the speed performance, but also does not reduce the stiffness performance. It is also proved that reducing small ball diameter is one of the development trends of main shaft bearing.

5. Influence of Initial Contact Angle

Under the condition of positioning preloading, with the increase of initial contact angle, the radial stiffness decreases significantly, while the axial and angular stiffness increases significantly. This is due to the increase of the initial contact angle, the radial component of the contact stiffness decreases, the axial component increases, and the contact load decreases under the same preload.

Under the condition of constant pressure preloading, the radial stiffness decreases significantly with the increase of initial contact angle; at low speed, the axial and angular stiffness increases, while at high speed, there is no change. This is because inner and outer rings allow axial displacement under constant pressure preloading, in order to keep the force balance, the outer ring contact angle is almost close to 0, and the initial contact angle has no effect on the outer ring contact angle. Similarly, with the increase of initial contact angle, the contact load decreases under the same preload.

Therefore, the axial and angular stiffness can be improved by increasing the initial contact angle under the positioning preloading, while the radial stiffness can be reduced by increasing the initial contact angle under the constant pressure preloading.